A septic system with a pump is a vital onsite wastewater treatment solution designed to overcome limitations in gravity flow. This article defines what it is, explains its mechanism, details its components and variations, outlines its benefits and applications, and discusses crucial considerations and common FAQs.

Table of Contents

What is a Septic System With Pump? The Complete Definition

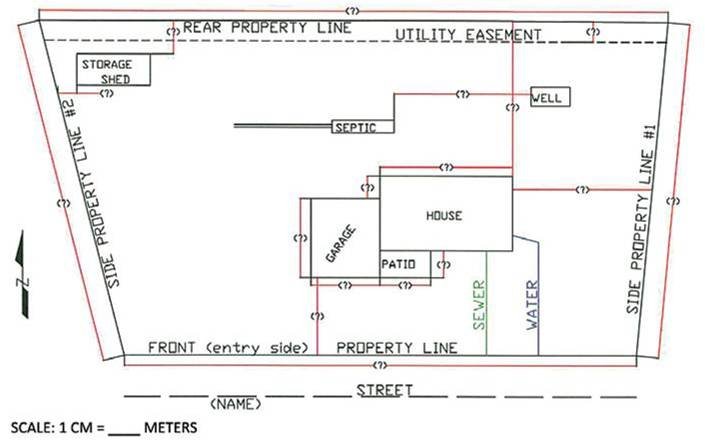

A septic system with a pump is a specialized type of onsite wastewater treatment system designed to overcome topographical or design challenges that prevent gravity-fed wastewater flow. Unlike traditional gravity systems where wastewater flows naturally downhill from the septic tank to the drain field, a septic system with pump incorporates a mechanical device to actively move effluent or raw sewage when gravity is insufficient. This design offers crucial flexibility, enabling septic solutions in locations previously deemed unsuitable due to site constraints like uphill drain fields, high water tables, or basements situated below the septic tank’s outlet.

Core Concept Explained Simply

At its core, a septic system with a pump functions by collecting wastewater in a primary septic tank for initial treatment (solids separation), similar to a conventional system. However, instead of flowing directly to a gravity-fed drain field, the partially treated wastewater (effluent) or sometimes raw sewage is directed into an intermediate chamber, often called a pump chamber or lift station. Within this chamber, an electric pump is installed. When the liquid level in the chamber reaches a predetermined point, a float switch activates the pump, which then pressurizes and propels the wastewater through a force main (a small-diameter pressure pipe) to its next destination, which could be an uphill drain field, an advanced treatment unit, or even a municipal sewer connection.

Key Terminology Breakdown

Understanding the specific terminology is essential for comprehending a septic system with a pump:

- Septic System Lift Station: A general term referring to a dedicated chamber containing one or more pumps designed to lift wastewater to a higher elevation or transport it over a longer distance. This can apply to effluent, raw sewage, or stormwater. In the context of a septic system, it specifically handles wastewater.

- Effluent Pump: A submersible pump designed to handle only liquid effluent—the clarified wastewater that has undergone primary treatment in the septic tank, meaning most solids have settled out. These pumps are robust but not designed for raw sewage containing large solids.

- Grinder Pump: A more powerful, specialized pump equipped with grinding blades or impellers that macerate (grind) solid waste, including human waste, toilet paper, and some soft food items, into a fine slurry before pumping it through a small-diameter force main. Grinder pumps are used when raw sewage needs to be moved directly from a building or a small collection tank, bypassing the primary settling function of a conventional septic tank.

- Float Switch: Electrical devices suspended in the pump chamber that detect liquid levels. They typically control the pump’s “on” and “off” cycles and may trigger an alarm if the liquid reaches an emergency high level.

- Pump Basin/Chamber: A watertight container, typically made of concrete or fiberglass, where the effluent or raw sewage collects before being pumped. It houses the pump, float switches, and associated piping.

- Force Main: The pressure pipe that carries wastewater under pressure from the pump to its discharge point. It must be designed to withstand internal pressure and external loads.

- Check Valve: A one-way valve installed in the force main, typically just after the pump, to prevent pumped wastewater from flowing back into the pump chamber when the pump shuts off.

Historical Development and Current Context

The early days of onsite wastewater management predominantly relied on gravity-fed systems due to their simplicity and reliability. However, as development expanded into more challenging terrains and property owners sought greater flexibility in building placement, the limitations of gravity became apparent. The development of submersible pumps in the mid-20th century provided a practical solution. Initially, these might have been less refined, but significant advancements in materials science, motor efficiency, and control technologies have made modern septic system lift station components highly reliable and energy-efficient.

Today, septic systems with pumps are standard components in septic system design for challenging sites. Modern systems often integrate smart controls, offering remote monitoring, predictive maintenance alerts, and more precise dosing capabilities for advanced treatment units. The focus continues to be on improving energy efficiency, enhancing durability, and ensuring seamless integration with diverse wastewater treatment technologies, aligning with stricter environmental regulations and the need for sustainable infrastructure.

How a Septic System With Pump Actually Works: The Mechanism

The operational mechanism of a septic system with a pump involves a sequence of steps, beginning with household waste generation and culminating in the controlled discharge of wastewater to a treatment area. This process ensures effective wastewater management even when natural gravity flow is not an option.

Fundamental Principles

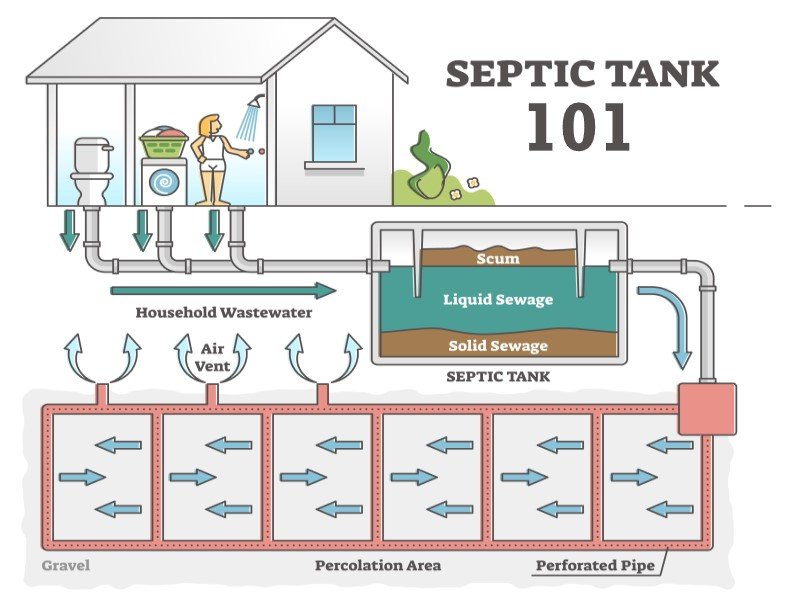

The fundamental principle governing a septic system with a pump is the controlled mechanical transfer of wastewater against gravity or over long distances. Wastewater from a home or business initially flows by gravity through plumbing lines to a septic tank. Here, primary treatment occurs: solids settle to the bottom (forming sludge), and lighter materials (like grease and oil) float to the top (forming scum). The clarified liquid, known as effluent, then exits the septic tank. In a pumped system, this effluent does not continue via gravity to a drain field. Instead, it flows into a separate pump chamber. Within this chamber, a pump is strategically placed. When the effluent level rises to a preset point, a float switch triggers the pump, which then forcefully pushes the effluent through a pressure pipe (force main) to its intended destination, overcoming any elevation changes or distances.

Process Flow Visualization

- Wastewater Generation: All water used in sinks, toilets, showers, and laundry in the household enters the main drainpipe.

- Septic Tank (Primary Treatment): Wastewater flows into the septic tank. Solids separate from liquids: heavy solids sink to form sludge, and lighter materials form a scum layer on top. Anaerobic bacteria begin to break down organic matter.

- Effluent Transfer to Pump Chamber: The partially treated liquid (effluent), which is in the middle layer of the septic tank, flows out of the septic tank’s outlet baffle and into a separate pump chamber.

- Effluent Accumulation: Effluent collects in the pump chamber until it reaches the “on” level of the activation float switch.

- Pump Activation: The rising effluent level lifts the “on” float switch, activating the effluent pump.

- Wastewater Pumping: The pump draws effluent from the bottom of the chamber and pushes it under pressure through the force main. A check valve prevents backflow when the pump is off.

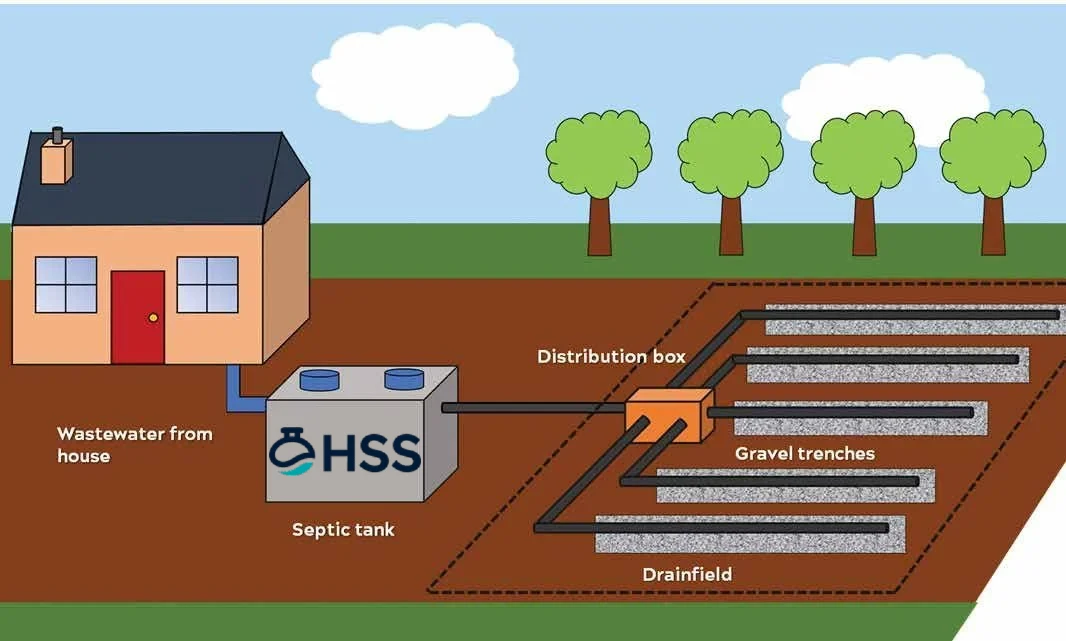

- Discharge to Drain Field/Treatment Unit: The pressurized effluent travels through the force main to the drain field, advanced treatment unit, or other designated discharge point, which may be located uphill or at a distance.

- Pump Deactivation: As the effluent level in the pump chamber drops to the “off” level, the pump’s “off” float switch disengages, turning the pump off until the chamber fills again.

- High-Level Alarm (Safety): A third float switch, set above the “on” float, will activate an audible and/or visual alarm if the liquid reaches an emergency high level, signaling a potential problem before a backup occurs.

For grinder pump systems, step 2 involves the grinder pump receiving raw sewage directly, grinding it, and then pumping it to the septic tank or municipal sewer.

Inputs, Processes, and Outputs

- Inputs: The primary input is all domestic wastewater generated from a property, including toilet waste (blackwater) and wastewater from sinks, showers, and laundry (greywater). This input volume fluctuates throughout the day based on household activity.

- Processes:

- Primary Treatment: In the septic tank, physical and biological processes separate solids and begin the breakdown of organic matter.

- Collection and Level Sensing: Effluent accumulates in the pump chamber, where float switches continuously monitor the liquid level.

- Pumping: Upon activation, the electric pump pressurizes and transfers the wastewater. Grinder pumps include an additional maceration process to reduce solids size.

- Flow Control: Check valves prevent backflow, ensuring one-way movement of wastewater. Control panels manage pump cycles and alarm systems.

- Outputs: The main output is the partially treated effluent or ground sewage, which is delivered to the next stage of treatment or disposal. This output is managed to ensure proper dispersal in the drain field or effective processing by advanced treatment units, preventing environmental contamination and property damage.

Components and Variations

A reliable septic system with a pump relies on several interconnected components, each playing a critical role in the effective management and transfer of wastewater. These systems also come in various configurations tailored to specific site needs and wastewater characteristics.

Main Parts and Their Functions

- Septic Tank: The initial and largest component, this watertight container holds wastewater for primary treatment. Solids settle, scum floats, and anaerobic bacteria begin decomposition.

- Effluent Filter (Optional but Recommended): Located at the outlet of the septic tank, this filter prevents larger suspended solids from flowing into the pump chamber, protecting the pump and the drain field from clogging.

- Pump Chamber/Basin: A separate, watertight tank designed to receive and temporarily store the effluent from the septic tank. It’s constructed to house the pump(s) and associated controls.

- Submersible Pump (Effluent or Grinder): The heart of the system.

- Effluent Pump: Specifically designed to move pre-treated liquid (effluent) with minimal suspended solids.

- Grinder Pump: Features cutting impellers to macerate raw sewage into a fine slurry before pumping. Used when solids cannot be pre-settled or when pumping directly from a building.

- Float Switches: Typically three are used:

- On Float: Activates the pump when effluent reaches a certain level.

- Off Float: Deactivates the pump when effluent drops to a lower level.

- High-Level Alarm Float: Triggers an alarm (audible/visual) if the effluent level rises above the normal operating range, indicating a pump failure or excessive inflow, preventing potential backups.

- Force Main: The durable, small-diameter pipe (typically PVC or HDPE) that transports the pressurized wastewater from the pump to the drain field or other discharge point.

- Check Valve: Installed in the force main, usually inside or just above the pump chamber, to prevent wastewater from flowing back into the chamber after the pump shuts off, reducing wear on the pump and preventing short-cycling.

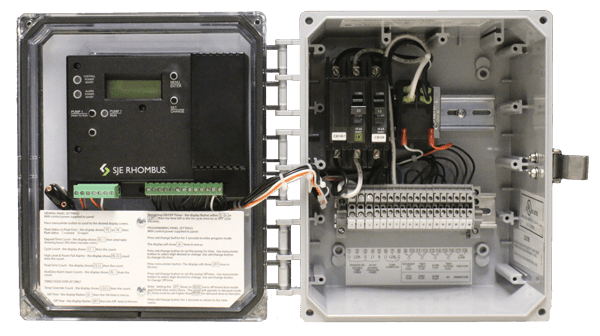

- Control Panel: An electrical enclosure, typically mounted above ground, that houses the motor starter, circuit breakers, and alarm circuitry. It provides power to the pump and controls its operation based on signals from the float switches, also displaying alarm status.

Different Models and Configurations

Septic systems with pumps are adapted into several models based on the type of wastewater handled and the system’s purpose:

- Effluent Pumping Systems: These are the most common configurations for

septic system designinvolving an uphill drain field. They handle partially treated effluent from a conventional septic tank. The pump chamber is separate from the septic tank. - Grinder Pump Systems: Used in situations where raw sewage needs to be moved directly from a building or a small collection tank to a septic tank, advanced treatment unit, or municipal sewer main located at a higher elevation or significant distance. These systems manage all solids at the point of origin.

- Dosing Septic Systems: A variant of effluent pumping systems where the pump delivers a specific, measured volume (dose) of effluent at programmed intervals to the drain field or advanced treatment unit. This allows for more even distribution across the absorption area, improving treatment efficiency and extending drain field life. Often used with pressure distribution drain fields.

- Timed Dosing Systems: Similar to dosing systems, but the pump operates on a timer, regardless of the effluent level, to ensure consistent intervals for sensitive advanced treatment processes or specialized dispersal methods.

- Multi-Pump Systems: For larger commercial applications or specific residential designs, two pumps might be installed in a single chamber (duplex system) for redundancy or to handle higher flow rates. They often alternate operation to ensure even wear.

Industry-Specific Versions

While the core principles remain, pump systems are adapted for various contexts:

- Residential Applications: Primarily for single-family homes with challenging topography, basement bathrooms, or advanced treatment units requiring pumped effluent.

- Commercial Applications: Restaurants, small businesses, or office buildings might use larger capacity grinder pump systems or effluent pump stations to handle higher volumes and potentially more diverse waste streams before connecting to a municipal sewer or a large-scale onsite treatment system.

- Community/Decentralized Systems: For small communities or subdivisions not connected to a central sewer system, multiple individual septic systems with pumps might discharge into a common force main network that leads to a cluster treatment facility or larger drain field. Here,

septic system lift stationbecomes a common term for central collection points. - Advanced Treatment System Integration: Many advanced aerobic treatment units (ATUs) or recirculating sand filters require pumped effluent for aeration, recirculation, or controlled dosing to optimize their biological treatment processes.

Benefits, Applications, and Impact

The integration of pumps into septic systems has significantly expanded their utility, addressing site limitations and enhancing treatment capabilities that were previously unattainable with purely gravity-fed designs.

Primary Advantages and Value Proposition

The key benefits of a septic system with pump revolve around flexibility, performance, and the ability to develop challenging sites:

- Overcoming Topographical Constraints: The most significant advantage is the ability to transfer wastewater uphill or across flat terrain where gravity flow is impossible. This opens up land for development that would otherwise be unusable for septic systems.

- Design Flexibility: Pumps allow for greater freedom in

septic system designand placement. The septic tank and drain field do not need to be contiguous or at the same elevation, enabling more optimal land use. This is particularly valuable for properties with limited space or specific landscape features. - Enabling Basement Bathrooms: For homes with basements, a pump system is often essential to lift wastewater from below-grade fixtures (toilets, showers, sinks) up to the main septic tank or directly to a force main, allowing for full functionality of basement living spaces.

- Enhanced Treatment Efficiency: Dosing systems, which rely on pumps, deliver effluent to the drain field in measured intervals. This promotes more uniform distribution and absorption, leading to improved soil treatment, reduced clogging, and extended life of the drain field. They are also crucial for many advanced aerobic treatment units that require precise effluent delivery.

- Reduced Excavation: While pumps add complexity, they can sometimes reduce the overall excavation required by allowing smaller-diameter force mains instead of large-diameter gravity pipes requiring extensive trenching with specific slopes.

Real-World Applications Across Industries

While predominantly a solution for residential properties, the principles of a septic system with a pump extend to various real-world scenarios:

- Residential Homes on Hilly Terrain: Properties built on hillsides or those where the only suitable drain field area is upslope from the house greatly benefit from a pump system.

- Homes with Basements: As mentioned, any below-grade plumbing requires a pump to move wastewater up to the septic system.

- Properties with High Water Tables: In areas prone to high groundwater, the drain field might need to be elevated to prevent saturation. A pump is necessary to lift the effluent to this elevated system.

- Advanced Treatment Systems: Many modern, higher-performance septic systems, such as aerobic treatment units (ATUs), require pumps to aerate wastewater, recirculate treated effluent, or dose it precisely into a specialized drain field.

- Remote Cabins or Outbuildings: For structures located far from a suitable septic drain field, a small grinder pump system can transport raw sewage over a long distance to the main septic tank.

- Small Commercial Establishments: Businesses like cafes, small offices, or remote gas stations might utilize a septic system with a pump to manage wastewater if they are not connected to a municipal sewer system.

Who Benefits Most and Why

- Homeowners with Challenging Lots: Individuals purchasing or building on properties with limited suitable land, significant elevation changes, or unsuitable soil conditions for gravity flow are primary beneficiaries. It allows them to develop their desired property.

- Developers and Builders: Pumps provide greater flexibility in subdividing land and designing homes, enabling projects on sites that would otherwise be deemed unbuildable from a wastewater perspective.

- Those Seeking Advanced Treatment: Property owners committed to higher levels of wastewater treatment for environmental reasons or due to stringent local regulations often rely on pumped systems to optimize the performance of aerobic units or other tertiary treatment options.

- Homeowners Desiring Full Basement Functionality: Anyone wanting to install a bathroom, laundry room, or wet bar in their basement where the plumbing fixtures are below the main septic line will require a pump.

- Rural Property Owners: Often located far from municipal services, rural properties frequently depend on onsite septic systems. Pumps expand the viable options for

septic system designin these settings.

Limitations and Considerations

While offering significant advantages, septic systems with pumps also come with their own set of limitations and considerations that property owners and designers must acknowledge. Understanding these aspects is crucial for long-term satisfaction and reliable operation.

Potential Drawbacks and Constraints

- Reliance on Electricity: Unlike purely gravity-fed systems, a

septic system with pumpis entirely dependent on electrical power to operate. Power outages can lead to backups if water usage is not curtailed or if a generator is not in place. - Higher Installation Costs: Installing a pump system is typically more expensive than a conventional gravity system due to the additional components (pump chamber, pump, floats, control panel, force main) and the electrical work required.

- Increased Maintenance Requirements: Pumps are mechanical devices subject to wear and tear. They require periodic inspection and servicing, and eventually, replacement. Float switches can also fail or become fouled. This adds to the long-term

septic system troubleshootingand maintenance burden. - Potential for Mechanical Failure: Pumps, like any mechanical equipment, can fail. This could be due to motor burnout, clogged impellers (especially with grinder pumps if inappropriate items are flushed), or electrical issues, leading to an overflow or backup.

- Alarm System Importance: While a high-level alarm provides early warning of a pump failure, ignoring it can still result in a significant problem. Property owners must be vigilant in responding to alarms.

- Noise (Grinder Pumps): Grinder pumps, particularly when located close to living spaces, can produce audible noise during their operation cycles, which might be a consideration for some homeowners.

- Vulnerability to Non-Biodegradable Items: Even grinder pumps have limits. Flushing excessive non-biodegradable items (wipes, feminine hygiene products, certain food waste, harsh chemicals) can still clog or damage the pump and associated plumbing.

Situations Where Alternatives Are Better

While pumps offer flexibility, a gravity-fed septic system is generally preferred if site conditions allow, primarily due to its simplicity, lower cost, and reduced reliance on mechanical components.

- Sufficient Natural Slope: If the property has a consistent downhill slope from the house, through the septic tank, and to a suitable drain field, a purely gravity-fed system is almost always the better choice. It eliminates the need for electricity, mechanical parts, and the associated maintenance and failure risks.

- Suitable Soil Conditions at Lower Elevation: When acceptable soil for a drain field is available at an elevation lower than the septic tank outlet, a gravity system is simpler and more cost-effective.

- Limited Budget: For homeowners with strict budget constraints for both installation and long-term maintenance, a gravity system is the most economical option.

- Remote Locations with Unreliable Power: In areas prone to frequent or prolonged power outages, or where connecting reliable electricity to a pump station is difficult or costly, alternative solutions (like composting toilets for blackwater combined with a greywater system) or a carefully designed passive system might be more resilient.

Common Misconceptions Debunked

- ”A pump means a poorly designed septic system.” This is false. Pumps are essential tools that enable proper

septic system designon challenging sites that would otherwise be undevelopable. They allow for optimal placement of drain fields away from wells, property lines, and sensitive areas, often leading to a better overall design solution. - ”Grinder pumps can handle anything you flush.” Incorrect. While grinder pumps are robust, they are not industrial shredders. Items like disposable wipes (even “flushable” ones), feminine hygiene products, excessive grease, plastics, or harsh chemicals can still clog pumps, damage impellers, or harm the overall septic system. Strict discipline regarding what goes down the drain is still required.

- ”Septic pumps run constantly.” Not true. Septic pumps operate intermittently. They activate only when the liquid level in the pump chamber reaches the “on” float and run until the level drops to the “off” float. The frequency depends on household water usage.

- ”A septic pump is just like a sump pump.” While both move water, they are designed for different purposes and waste characteristics. Septic effluent pumps are built to handle wastewater containing small solids and corrosive elements, while grinder pumps are specifically designed for raw sewage. Sump pumps are typically for clear groundwater. Using the wrong type of pump can lead to rapid failure and system damage.

- ”Pumps are always noisy and smelly.” Modern effluent pumps are generally quiet in operation, submerged in liquid within a sealed chamber. While grinder pumps can be audible when active, they are also sealed. Any persistent noise or odor usually indicates a problem requiring

septic system troubleshooting.

Frequently Asked Questions

What are the main reasons a septic system needs a pump?

A septic system typically requires a pump when the drain field or advanced treatment unit is located uphill from the septic tank, or if the land is too flat to provide adequate gravity flow. Pumps are also necessary to move wastewater from basement fixtures that are below the main septic line or to provide controlled dosing for enhanced treatment systems.

How often should a septic pump be serviced?

The frequency of service depends on the pump type, system usage, and manufacturer recommendations. Generally, effluent pumps should be inspected annually by a qualified technician during routine septic system maintenance. Grinder pumps, due to handling raw sewage, might benefit from more frequent checks.

What causes a septic pump alarm to go off?

A septic pump alarm typically indicates that the water level in the pump chamber is too high, signaling a problem. Common causes include a failed pump, a tripped circuit breaker, a faulty float switch, a blockage in the force main, or excessive water usage overwhelming the pump’s capacity.

How long do septic pumps typically last?

The lifespan of a septic pump varies widely based on pump quality, usage patterns, and maintenance. Effluent pumps generally last between 7-15 years, while grinder pumps, due to their more demanding function, might have a lifespan of 5-10 years. Proper installation, regular maintenance, and avoiding flushing inappropriate items can extend their life.

Can I put a septic pump inside my existing septic tank?

Generally, no. Effluent pumps are typically installed in a separate pump chamber after the septic tank. Installing a pump directly into the septic tank can agitate the settled solids, disrupt the anaerobic treatment process, and risk pumping solids into the drain field, leading to premature failure and system damage.

What should I do if my septic pump stops working during a power outage?

During a power outage, the septic pump will not operate. It is crucial to immediately conserve water by limiting or stopping all water usage in the household. Avoid flushing toilets, taking showers, or running laundry or dishwashers until power is restored and the pump resumes normal function.

What is the difference between an effluent pump and a grinder pump?

An effluent pump handles partially treated liquid wastewater (effluent) that has already passed through the septic tank, meaning most solids have settled out. A grinder pump, conversely, is designed to macerate (grind) raw sewage, including solids, into a fine slurry before pumping it. Grinder pumps are more robust and used for direct raw sewage transfer.

Do all septic systems have pumps?

No, not all septic systems have pumps. Many septic systems, especially on properties with sufficient natural downhill slope, are entirely gravity-fed. Pumps are added to septic systems specifically when gravity flow is not feasible due to topographical constraints or when advanced treatment systems require controlled dosing.

How much electricity does a septic pump use?

The electrical consumption of a septic pump varies depending on its horsepower and how frequently it runs. While they require electricity, they typically operate intermittently, meaning their overall energy usage might be less than anticipated. Most residential pumps are designed to be energy-efficient for their duty cycle.

What is the purpose of the check valve in a septic pump system?

The check valve in a septic pump system prevents the wastewater that has just been pumped up the force main from flowing back down into the pump chamber when the pump turns off. This prevents unnecessary refilling of the chamber, reduces the pump’s workload, and avoids short-cycling, thus extending the pump’s lifespan.

— Bottom Line: Septic systems with pumps are essential for properties with challenging topography, enabling effective wastewater management where gravity alone is insufficient. While they require electricity and more maintenance than gravity systems, their flexibility and ability to integrate with advanced treatment technologies make them invaluable for modern onsite sewage disposal.

Pump failure leads to backups. Consider pump alarm installation and contact with local service providers.

Key Points:

- Septic systems with pumps move wastewater when gravity isn’t enough.

- They use an electric pump activated by float switches in a pump chamber.

- Common types include effluent pumps (for treated liquid) and grinder pumps (for raw sewage).

- Key benefits include overcoming elevation challenges and enabling flexible site design.

- Limitations include reliance on electricity and higher maintenance needs.

- Gravity systems are preferred if site conditions permit due to simplicity.

- Proper maintenance and avoiding flushing inappropriate items are crucial for longevity.

Keep Reading:

- Understanding Gravity-Fed Septic Systems

- The Benefits of Aerobic Septic Systems

- How Often Should You Pump Your Septic Tank?

- Essential Septic System Maintenance Guide

- Choosing the Right Septic System Design for Your Property

Leave a Reply