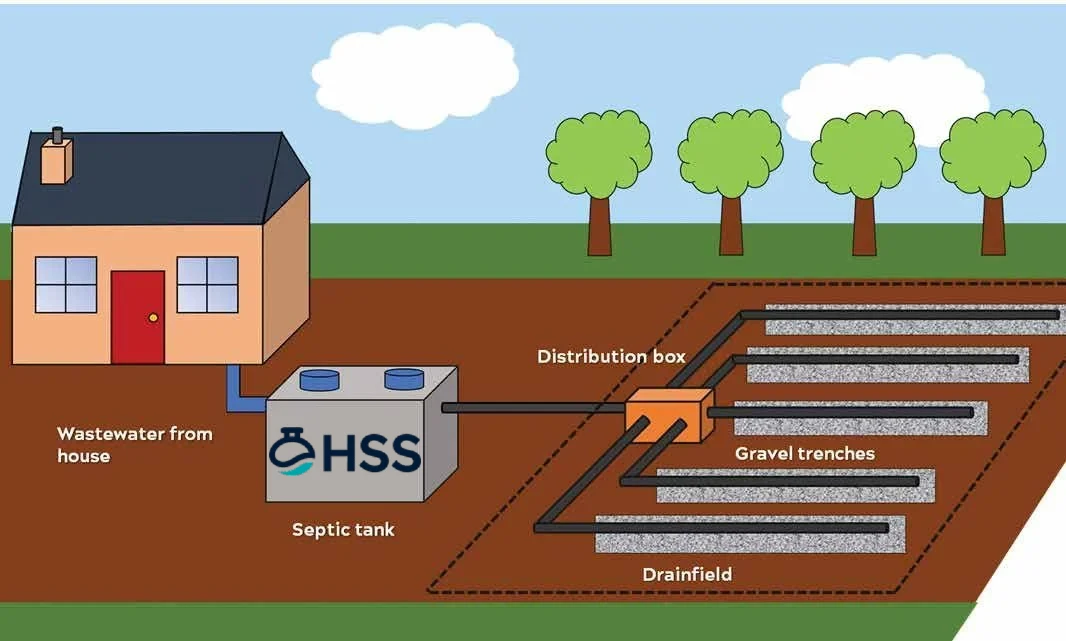

The efficiency and longevity of any septic system depend on the harmonious function of its various septic system parts. While the septic tank often receives the most attention, an equally crucial, though often overlooked, component is the septic system distribution box, commonly known as a D-box. This unassuming structure plays a pivotal role in ensuring the treated wastewater from your septic tank is evenly distributed across your septic system leach field. Without a properly functioning D-box, the leach field can become overloaded in certain areas, leading to premature failure, system backup, and costly repairs. Understanding its function is key for any homeowner aiming to maintain a healthy and compliant septic system.

Deep Dive: Understanding the Septic System Distribution Box

Detailed Definition and Components

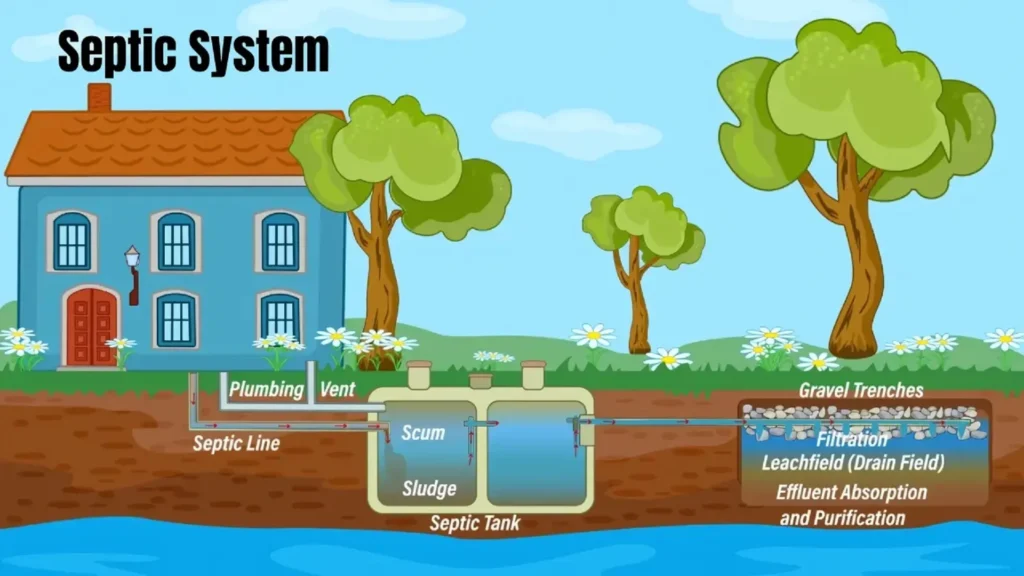

A septic system distribution box is a watertight container, typically made of concrete or high-grade plastic, installed between the septic tank and the leach field. Its primary purpose is to receive the partially treated effluent from the septic tank and divide it equally among the multiple trenches or laterals of the leach field.

Key components of a D-box include:

- Inlet Pipe: Connects directly from the septic tank outlet.

- Outlet Pipes: Multiple pipes (typically 2-5 or more, depending on system design) that connect to individual leach field laterals.

- Internal Baffles/Weirs: Some designs incorporate internal structures to help settle any remaining solids and ensure uniform flow, though the primary mechanism for even distribution is achieved by proper leveling of the D-box itself.

- Access Lid: A removable cover, often at ground level or just below, allowing for inspection and maintenance.

The D-box must be installed perfectly level to ensure that effluent flows out of all outlet pipes at an equal rate, preventing hydraulic overloading of any single leach field section.

How It Functions Within the Larger System

After wastewater enters the septic tank, heavier solids settle to the bottom and lighter scum floats to the top. The clarified liquid (effluent) then flows out of the tank’s outlet pipe and into the septic system distribution box. Inside the D-box, the effluent collects until the water level rises to the height of the outlet pipes. Because the D-box is designed to be level, the effluent then flows simultaneously and evenly into each of the connected leach field laterals.

Each lateral pipe in the leach field typically has perforations that allow the effluent to seep into the surrounding gravel and soil, where it undergoes final treatment by natural biological processes. An even distribution of effluent by the D-box is critical. If one part of the leach field receives too much wastewater, its soil absorption capacity can be quickly overwhelmed, leading to saturated spots, surface ponding, and eventual failure of that section, putting undue stress on the entire septic system design.

Visual Breakdown

(Image: component-diagram) A diagram illustrating a cross-section of a septic system distribution box, showing the inlet pipe from the septic tank, the internal chamber, multiple outlet pipes leading to different leach field laterals, and the importance of a level installation for even flow.

Practical Applications and Real-World Scenarios

The septic system distribution box plays a continuous, vital role throughout the life of a septic system, from its initial installation to ongoing maintenance and potential repairs.

Use Case 1: New Septic System Installation

During the installation of a new septic system, the precise placement and leveling of the D-box are paramount. Engineers and installers meticulously calculate the required size and number of leach field laterals based on soil absorption rates and household water usage, as recommended by the Environmental Protection Agency (EPA) for onsite systems. The D-box is then installed to connect these laterals, ensuring each trench receives its calculated share of effluent. Proper initial installation prevents uneven loading from day one, maximizing the lifespan of the entire septic system leach field.

Use Case 2: Septic System Repair/Upgrade

If a homeowner experiences localized wet spots in their yard, foul odors, or slower drains specifically linked to a particular section of the leach field, the D-box is often a primary suspect. Damage, settling, or a clog within the D-box can disrupt the even distribution. In such cases, repair might involve cleaning the D-box, releveling it, repairing cracks, or, if the damage is extensive, replacing the entire unit. Upgrading an older system might also involve replacing an outdated or undersized D-box to better accommodate modern water usage patterns or a re-designed leach field.

Industry-Specific Applications

While most commonly associated with residential septic system design, the principles behind a distribution box are applied in various decentralized wastewater treatment systems. Larger commercial or community septic systems, often overseen by organizations like the National Environmental Health Association (NEHA), may utilize more complex header boxes or multiple D-boxes to manage higher volumes of effluent and larger leach field footprints. Regardless of scale, the fundamental need for uniform distribution to prevent hydraulic overload remains a cornerstone of efficient septic system parts functionality.

Implementation Guide

While homeowners typically do not install a septic system distribution box themselves, understanding the process involved in its installation or replacement provides valuable insight into proper septic system design and maintenance.

Step-by-Step Process

- Site Assessment and Design: A licensed professional surveys the site, determines soil conditions, and designs the leach field layout, specifying the D-box location and required outlet connections, adhering to local health department guidelines.

- Excavation: The area for the D-box is excavated to the precise depth required for proper gravity flow from the septic tank and to the leach field laterals.

- D-box Placement and Leveling: The distribution box is carefully positioned in the excavated area. This is the most critical step; using a level, the installer ensures the box is perfectly horizontal across all axes, so all outlet ports are at the exact same elevation.

- Pipe Connections: The inlet pipe from the septic tank is connected, and the outlet pipes leading to each leach field lateral are securely attached, often using watertight seals or flexible couplers.

- Water Testing (Optional but Recommended): Water is run through the D-box to visually confirm even outflow from all ports before backfilling.

- Backfilling and Access Riser Installation: The area around the D-box is carefully backfilled, taking care not to disturb its level position. An access riser may be installed over the D-box lid to bring the access point to ground level for easier future inspection.

- Final Grading: The ground is graded to ensure proper surface water drainage away from the septic system components.

Required Tools and Resources

Professionals undertaking D-box installation or replacement utilize a range of tools, including:

- Excavation equipment (mini-excavators, shovels)

- Surveying equipment (transits, laser levels)

- High-quality spirit levels

- Pipe cutters and joining tools

- Watertight sealants and couplers

- New

septic system distribution box(concrete or plastic) - Gravel or crushed stone for bedding

- Measuring tapes and markers

Timeline and Milestones

The installation of a new septic system distribution box as part of a complete septic system can take several days, depending on site conditions and the complexity of the leach field. A D-box replacement in an existing system, assuming the leach field is intact, might be completed within a day or two, including excavation, installation, and backfilling. Key milestones include successful excavation, precise leveling of the D-box, watertight pipe connections, and verified even flow before final backfill.

Integration and Optimization

The septic system distribution box does not operate in isolation; its performance is intrinsically linked to other septic system parts and overall system health. Understanding these connections is vital for optimization.

How This Connects to Septic Tank Pumping

How This Connects to Leach Field Health

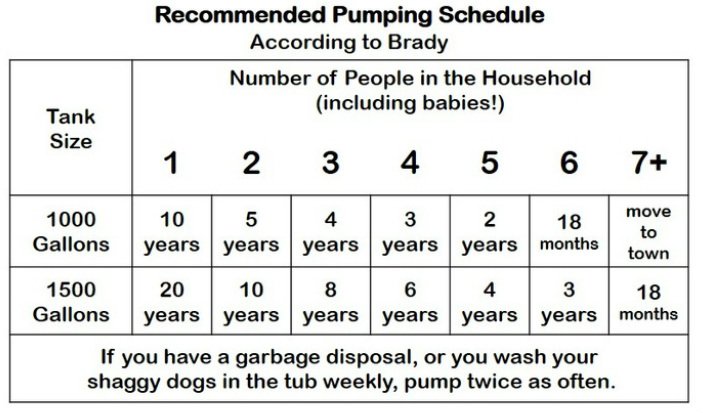

Regular septic tank pumping is a critical maintenance task to protect your distribution box and leach field. Over time, sludge and scum accumulate in the tank. Without scheduled pumping, these solids can flow out with the effluent, bypass the outlet baffle, and enter the distribution box. Clogs within the D-box or its outlet pipes—often a direct result of neglected pumping—disrupt effluent distribution and can compromise the entire system.

Optimization Tips for Maximum Efficiency

To optimize the performance and extend the life of your septic system distribution box and the entire septic system:

- Ensure Proper Leveling: The most critical factor. During installation or any repair, confirm the D-box is perfectly level. Even a slight tilt can significantly impact distribution.

- Regular Inspections: During septic tank pumping, ask your professional to inspect the D-box. They can check for cracks, settling, or blockages.

- Prevent Solids Entry: Adhere to regular septic tank pumping schedules. Avoid flushing non-biodegradable items or excessive grease, which can bypass the tank and clog the D-box.

- Proper Water Usage: Minimize excessive water usage, as it can overwhelm the entire system, including the D-box’s ability to distribute effectively.

- Protect from Damage: Avoid driving heavy vehicles or constructing structures over the D-box or leach field area, which can cause crushing or settling.

Troubleshooting This Specific Aspect

Issues with the septic system distribution box often manifest as problems in the septic system leach field. Early detection and appropriate action can prevent more severe and costly failures.

Common Problems and Symptoms

- Uneven Leach Field Saturation: The most common symptom. You might notice persistently wet, spongy, or unusually green areas in one part of your leach field, while other areas remain dry.

- Foul Odors: Persistent sewage smells around the leach field or D-box area, indicating surfacing effluent.

- Slow Drains or Backups: While often originating in the septic tank or plumbing, recurrent slow drains or backups could point to an overwhelmed leach field due to D-box issues.

- Visible Cracks or Damage: If the D-box access riser is at grade, physical damage to the lid or visible cracks in the box itself can be a sign.

- Settling: The ground above the D-box appears to have sunk, suggesting the box itself may have settled and is no longer level.

- Clogs: Effluent levels inside the D-box are consistently higher than the outlet pipes, or one or more outlet pipes are completely blocked by solids.

Diagnostic Flowchart

(Image: flowchart) A flowchart illustrating the diagnostic process for a homeowner suspecting D-box issues. It starts with observing symptoms (wet spots, odors), moves to checking septic tank pumping records, then suggests professional D-box inspection (checking for level, cracks, clogs), and finally recommends solutions based on findings.

Solutions for Each Issue

- Unlevel D-box: If the D-box has settled, it may be possible for a professional to carefully excavate around it and re-level the box, often by shimming it with gravel or concrete.

- Clogged Outlet Pipes/Internal: A professional can often clear blockages by jetting or snaking the outlet pipes from within the D-box. Any accumulated sludge in the D-box itself can be removed.

- Cracked D-box: Minor cracks might be repaired with waterproof patching compounds. However, significant structural cracks typically necessitate replacement of the entire

septic system distribution boxto ensure watertight integrity and proper function. - Damaged/Missing Lid: Replace the lid immediately to prevent debris entry and accidental fall-ins.

When to Call a Professional

Diagnosing and repairing D-box issues often requires excavation and specialized knowledge. It is highly recommended to call a licensed septic professional if you:

- Observe any of the common problems listed above.

- Need to locate your D-box for inspection.

- Suspect your D-box is unlevel, cracked, or severely clogged.

- Require any repair or replacement of

septic system parts.

Attempting DIY repairs without proper expertise can worsen the problem, lead to further system damage, and potentially contaminate your property or local environment.

Maintenance Schedule and Best Practices

While the septic system distribution box is a robust component, specific maintenance practices ensure its long-term reliability and the overall health of your septic system design.

Daily/Weekly Tasks

- Visual Leach Field Check: Routinely walk across your

septic system leach fieldarea. Look for unusually wet or spongy spots, standing water, or unusually lush, green grass that might indicate surfacing effluent. Early detection of these symptoms can point to D-box issues. - Odor Detection: Be attentive to any foul, sewage-like odors emanating from the septic area. This can be an early indicator of a problem.

Monthly/Quarterly Checks

- Monitor Water Usage: Be mindful of your household’s water consumption. While not a direct D-box check, managing water usage prevents overwhelming the entire

septic system design, including the D-box and leach field. - Avoid Overloading: Ensure you are not flushing non-biodegradable items or excessive grease, which can contribute to clogs in the D-box or leach field laterals.

Annual Review and Updates

- Professional Inspection: During your routine septic tank pumping (typically every 3-5 years, depending on household size and tank volume), specifically ask the professional to inspect your septic system distribution box. They should check:

- If it is level.

- For any sludge buildup or blockages at the inlet or outlet pipes.

- For cracks or structural damage.

- The condition of the outlet pipes leading to the leach field.

- Update Records: Keep accurate records of all septic system inspections, pumping dates, and any repairs made to the D-box or other septic system parts. This historical data is invaluable for tracking performance and planning future maintenance.

Conclusion and Pathways Forward

The septic system distribution box may be out of sight, but it is far from out of mind when it comes to the effective operation and longevity of your septic system. Its critical role in evenly distributing effluent to the leach field protects this costly asset from premature failure, ensuring your wastewater is properly treated and your property remains healthy and odor-free. Ignoring this vital component can lead to localized leach field issues, requiring significant excavation and expense to remedy.

By understanding how the D-box functions, recognizing common problems, and adhering to a proactive maintenance schedule, homeowners can contribute significantly to the overall health and efficiency of their septic system design. Regular professional inspections, particularly during septic tank pumping, are your best defense against unexpected D-box failures. For a deeper understanding of your entire wastewater system, explore our comprehensive guide on the Essential Guide to Your Home Septic System.

Bottom Line: Uneven drainage in your field? Have a pro check the distribution box level and outflow.

Frequently Asked Questions

What is the purpose of a septic system distribution box?

The primary purpose of a septic system distribution box (D-box) is to receive clarified effluent from the septic tank and distribute it equally among the various absorption trenches or laterals of the septic system leach field. This ensures no single section of the leach field becomes overloaded, which helps prolong the system’s life.

How do I locate my septic system distribution box?

The septic system distribution box is typically located between the septic tank and the septic system leach field. You can often find its general location by looking at your septic system’s “as-built” diagram or by probing the ground between the tank and the start of your leach field. Professionals use specialized tools to pinpoint its exact position.

What happens if a distribution box is not level?

If a septic system distribution box is not level, effluent will flow unevenly, directing more wastewater to the lower-lying outlet pipes and corresponding leach field laterals. This leads to hydraulic overloading and premature failure of those sections of the septic system leach field, causing wet spots, odors, and potential backups.

Can a distribution box get clogged?

Yes, a septic system distribution box can become clogged with solids, sludge, or grease that escape the septic tank, especially if the tank is not pumped regularly or if the outlet baffle is damaged. Clogs prevent even distribution and can lead to system failure.

How often should a distribution box be inspected?

The septic system distribution box should ideally be inspected every time your septic tank is pumped, which is typically every 3-5 years. During this inspection, a professional will check its level, look for cracks, and ensure all outlet pipes are clear of blockages.

Is it possible to repair a damaged distribution box?

Minor cracks or blockages in a septic system distribution box can sometimes be repaired by a professional. However, if the box is severely cracked, collapsed, or has significantly settled and cannot be re-leveled, replacement is usually the necessary course of action.

Can I replace my septic system distribution box myself?

Replacing a septic system distribution box involves excavation, precise leveling, and proper pipe connections, often requiring permits and inspections. It is a complex task best left to licensed septic professionals to ensure compliance with local regulations and proper septic system design and function.

Keep Reading:

- Septic Tank Pumping: Your Essential Guide

- Maintaining Your Septic System’s Leach Field

- Understanding Your Home Septic Tank Maintenance

- The Essential Guide to Your Home Septic System

External Resources:

- Environmental Protection Agency (EPA) – Septic Systems (https://www.epa.gov/septic)

- National Environmental Health Association (NEHA) – Onsite Wastewater (https://www.neha.org/focus-areas/onsite-wastewater)

- State or Local Health Department (e.g., specific state’s department of environmental quality septic system information)

Leave a Reply