Quick Answer: A mound septic system is an engineered wastewater treatment solution ideal for properties with poor soil conditions or high water tables. By elevating the drain field above ground and using a precisely layered bed of sand and gravel, mound systems ensure safe effluent filtration where conventional underground systems would fail.

- Mound septic systems are essential for sites with unsuitable soil or high groundwater.

- They use a multi-layered mound (sand, gravel, pipes) to treat and disperse wastewater safely above ground.

- Expert design, proper installation, and regular maintenance are crucial for reliable performance.

- Signs of trouble include surface pooling, odors, or irregular pump operation—requiring prompt action.

Table of Contents

Introduction: The Critical Role of Mound Septic Systems

For homeowners dealing with poor soil conditions—such as clay-heavy earth or a high water table—a traditional underground septic system is often unworkable. The mound septic system addresses this challenge by elevating the drain field above ground, delivering effective wastewater treatment where conventional systems would otherwise fail. Understanding mound septic systems is essential for proper design, installation, and ongoing maintenance in landscapes unsuitable for standard septic options. This article delivers a comprehensive technical overview of mound systems, explaining their design, performance nuances, advantages, drawbacks, and optimum maintenance routines.

Deep Dive: Understanding Mound Septic Systems

Detailed Definition and Components

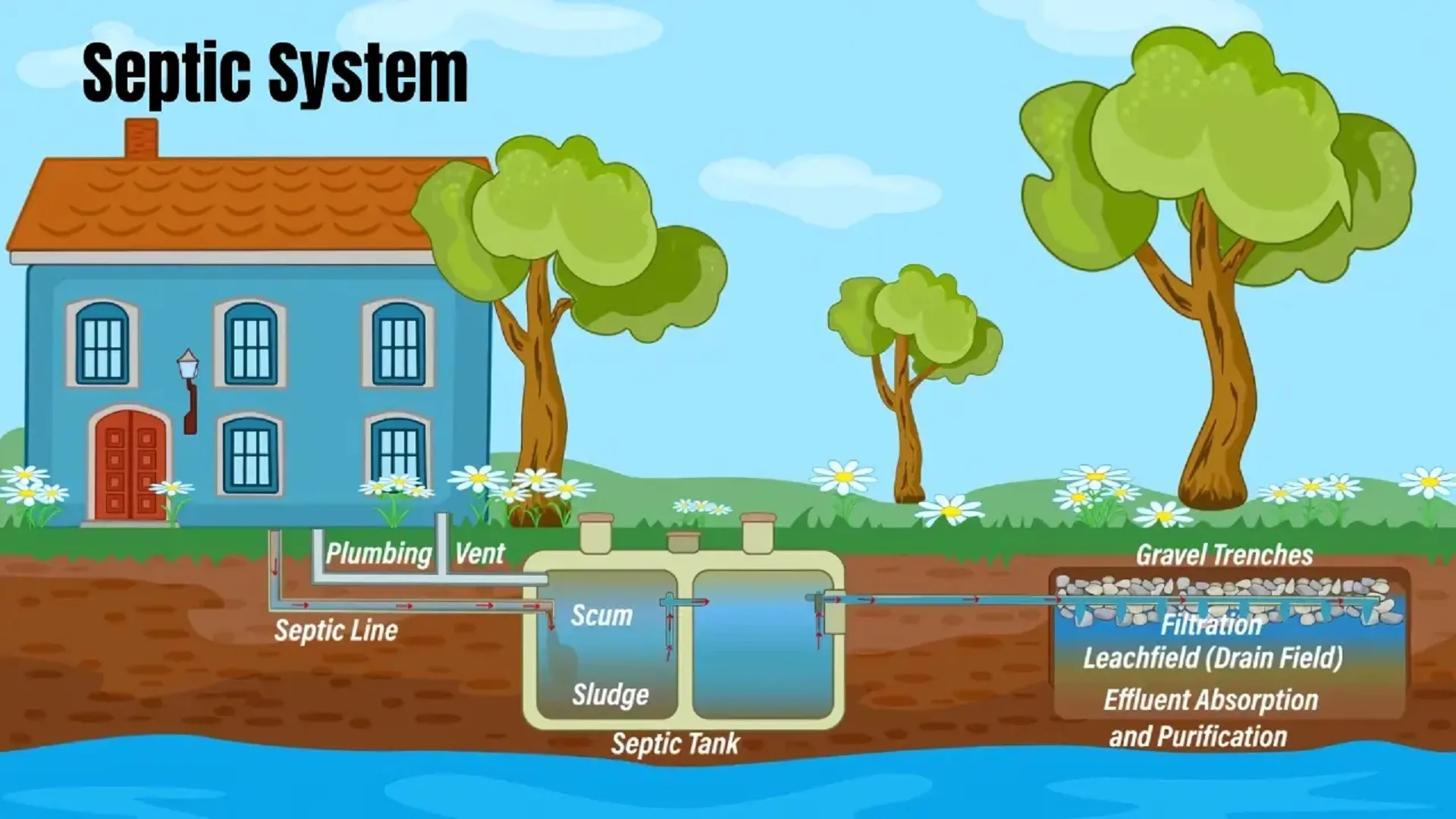

A mound septic system is an engineered on-site wastewater treatment solution specially designed for properties where absorption is poor or groundwater is high. The main components include:

| Component | Description | Purpose |

|---|---|---|

| Septic Tank | Initial tank where solids settle out of wastewater. | Primary separation and partial breakdown of waste. |

| Dosing Chamber | Secondary tank that collects effluent from septic tank and regulates flow. | Ensures timed, consistent distribution to mound. |

| Sand Mound | Engineered layer of sand above native soil. | Filtration and aerobic treatment of effluent. |

| Gravel Bed & Pipes | Layer above the sand containing perforated distribution pipes surrounded by gravel or stone. | Even dispersal of treated effluent through the mound. |

| Vegetative Cover | Top soil with grass or non-woody plants. | Prevents erosion and facilitates oxygen exchange. |

Wastewater first collects in the septic tank, then flows to the dosing chamber, which pumps pre-treated effluent into the sand mound at set intervals. The sand and gravel foster microbial breakdown and filtration as effluent is evenly dispersed and treated before reaching the soil surface above natural grade.

How It Functions Within the Larger System

The mound system replaces the conventional subsurface drain field with a controlled, elevated mound that enables aerobic treatment and safe effluent dispersal. Effluent is distributed at measured intervals by the dosing chamber pump, ensuring maximum bacteria-mediated treatment. Integration with household plumbing and septic tanks is standard, but precise design adjusts for each site’s unique slope and soil profile.

Practical Applications and Real-World Scenarios

Use Case 1: Septic System for Wet Areas

In areas with a high water table, conventional drain fields become saturated, risking environmental contamination or outright failure. The mound system elevates the filtration zone above saturated soil, providing a safe buffer—especially valuable in coastal or flood-prone zones where water is close to the surface.

Use Case 2: Septic System on a Slope

Sloped properties pose challenges for gravity drainage and even effluent distribution. Mound systems can be crafted with level, terraced sand beds and use dosing mechanisms to assure gentle, non-erosive dispersal even on gradients. Modular design helps tailor the system to fit sloped sites, preventing runoff and uneven absorption.

Industry-Specific Applications

Mound septic systems are also used in commercial and agricultural settings where environmental regulations prohibit traditional layouts. Facilities such as campgrounds, rural resorts, and farms employ mound systems to provide robust, regulatory-compliant treatment solutions in sites with unsuitable soils.

Implementation Guide

Step-by-Step Process

- Site Evaluation and Soil Testing: Conduct percolation tests and site slope analysis to assess feasibility and inform precise system design.

- Design Engineering: Create engineering drawings specifying mound dimensions, sand/gravel layers, dosing regimen, and pipe layout.

- Permitting and Compliance: Secure permits and approvals from health and environmental authorities following local code.

- Excavation and Base Preparation: Clear and grade site, prepare a level base for mound foundation.

- Layer Construction: Install septic tank, dosing chamber, sand and gravel mound layers, distribution pipes, and geotextile cover.

- System Testing: Test dosing pump operation, check for uniform distribution, and ensure correct flow using water prior to final backfill.

- Final Inspection and Commissioning: Pass regulatory inspection, finalize landscape restoration, and establish a maintenance schedule for the homeowner.

Required Tools and Resources

- Soil probe & percolation test kits

- Excavation equipment (backhoe, grader)

- Dosing pump and control panel

- Engineered sand and gravel materials

- PVC distribution piping, geotextile fabrics

- Environmental monitoring instruments

Timeline and Milestones

| Timeframe | Milestone |

|---|---|

| Week 1-2 | Site assessment, soil testing, design completion |

| Week 3 | Permitting and regulatory approvals |

| Week 4-5 | Site excavation, base prep, and mound construction |

| Week 6 | System testing, inspection, commissioning |

Integration and Optimization

How This Connects to Conventional Septic System Design Principles

While mound septic systems are based on conventional septic design fundamentals, they incorporate engineered, above-grade dispersion. Mastering conventional septic system design principles helps professionals and homeowners successfully adapt these innovations to challenging soil or water table scenarios.

How This Connects to Advanced Wastewater Treatment Options

Mound systems can be integrated with aerobic treatment units or enhanced dosing controls, serving as a bridge between basic septic treatment and advanced wastewater technology when higher-level filtration and disinfection are required.

Optimization Tips for Maximum Efficiency

- Calibrate dosing pump on a schedule for consistent, even effluent distribution.

- Maintain a healthy vegetative cover (deep-rooted grasses preferred) to stabilize soil and promote oxygen transfer.

- Keep vehicles and heavy equipment off the mound to prevent compaction and system damage.

- Schedule inspections semi-annually to identify early signs of sand clogging, pump issues, or surface erosion.

Troubleshooting This Specific Aspect

Common Problems and Symptoms

- Effluent surfacing on the mound: Usually signals clogging, overloading, or compaction.

- Uneven vegetation growth: May indicate distribution imbalances or saturated soil.

- Pump failure or irregular dosing: Points to electrical, float switch, or pump problems.

- Persistent odors near the mound or septic tank: Indicates incomplete treatment or blocked venting.

Diagnostic Flowchart

See attached diagram for a stepwise diagnosis of mound surfacing, dosing failures, and vegetation symptoms.

Solutions for Each Issue

- For effluent surfacing, check for soil compaction, and regrade mound if required. Clean or replace filters in the dosing chamber.

- Promptly repair or replace dosing pump components and floats to restore regular dosing cycles.

- If sand layers are clogged, aerate or replace as necessary—consult professionals for severe cases.

- Reduce household water usage or adjust dosing schedule to correct overloading issues.

When to Call a Professional

If basic troubleshooting fails or if significant repairs are indicated, consult certified mound septic system professionals. Reliable service is vital for pump replacement, mound reconstruction, and ensuring ongoing compliance with environmental standards per EPA and local health agencies.

Maintenance Schedule and Best Practices

Daily/Weekly Tasks

- Monitor dosing pump indicator lights and alarms for warnings.

- Check regularly for odors around the mound.

- Ensure yard drainage directs rainwater away from the mound.

Monthly/Quarterly Checks

- Inspect vegetation, repair any bare or eroded spots.

- Clean or swap dosing chamber filter screens as needed.

- Test pump and control panel functions, including backup systems.

Annual Review and Updates

- Schedule a system-wide inspection by a licensed on-site wastewater professional, including percolation re-check.

- Arrange septic tank pumping every 3-5 years, or as system use dictates.

- Review and update the homeowner maintenance log and revise guidelines as necessary.

Conclusion and Pathways Forward

Mound septic systems offer a vital, engineered alternative for properties where conventional solutions cannot succeed due to challenging site conditions. Their carefully layered sand and gravel construction, precise dosing controls, and engineered distribution ensure effective, safe wastewater treatment above natural ground level. With knowledgeable design, quality installation, and diligent maintenance, homeowners can expect decades of reliable performance.

For properties with marginal soil or fluctuating seasonal groundwater, collaborating with experienced septic professionals is crucial. For a broader understanding, see our Comprehensive Guide to Septic System Types or reach out for local expert advice.

Download our Mound Septic System Maintenance Checklist to help keep your system running smoothly.

Frequently Asked Questions

What is the primary reason for installing a mound septic system?

The main reason is to enable safe on-site wastewater treatment in soil that cannot absorb effluent safely due to high groundwater, impermeable clay, or shallow bedrock. The mound elevates the drain field above ground for proper filtration, as verified by EPA and CDC guidelines (EPA Septic Systems Guide).

How is a mound septic system different from a conventional system?

Conventional systems rely on underground soil absorption. Mound systems use an engineered, above-ground mound with sand and gravel, plus dosing pumps, to manage effluent where native soils are unsuitable.

Can a mound septic system be installed on sloped land?

Yes. These systems are often engineered on sloped sites using terraced mounds and controlled pumps, ensuring even distribution and preventing runoff or erosion.

What are common maintenance requirements for mound septic systems?

Regular pump operation checks, system inspections, maintenance of vegetative cover, periodic septic tank pumping, and protecting the mound from heavy traffic or compaction are key.

Why is sand used in a mound septic system?

Sand serves as a crucial aerobic filtration layer, enabling microbial treatment before effluent enters the natural soil—vital for purification when native soils lack filtering ability, as confirmed in NOWRA studies.

How often should the dosing pump be inspected?

At least monthly. Regular inspection of pump operation, floats, and backup systems is recommended to catch and correct issues promptly.

What are the signs of mound system failure?

Warning signs include effluent surfacing on the mound, persistent odors, standing water, dead vegetation patches, or frequent pump alarms—each indicating maintenance or repairs are needed.

Leave a Reply