The best septic system for clay soil, small lots, or sites with high water tables is an engineered alternative system, such as a mound system or an Aerobic Treatment Unit (ATU). These are specifically designed by licensed professionals to overcome poor percolation, space limitations, and environmental regulations where conventional systems fail.

Key Factors:

- Soil Type: Clay is impermeable, requiring systems built above grade (mounds) or advanced treatment (ATUs).

- Lot Size: Small lots benefit from compact dispersal methods like drip irrigation or spray fields.

- Site Conditions: High bedrock or water tables mandate above-ground or shallow dispersal solutions.

- Regulations: Sensitive environmental areas often require the highest treatment level (ATUs).

Table of Contents

Your Challenging Site Has a Proven Solution

The core problem is solvable. If you’ve been told your property has “unbuildable” soil or insufficient space for a conventional septic system, you are facing a common issue—not a dead end. According to the USDA, nearly one-third of U.S. soils have clay-heavy or hydric layers that fail standard percolation tests. The emotional and financial stress of a stalled building project or a failing system is significant. However, modern septic engineering provides reliable, health-department-approved solutions designed explicitly for difficult conditions like clay soil, small lots, high water tables, and shallow bedrock. This guide synthesizes expert plumbing and environmental engineering perspectives to provide a clear action plan, turning your site limitation into a manageable, permitted project.

Why Won’t a Conventional Septic System Work on My Property?

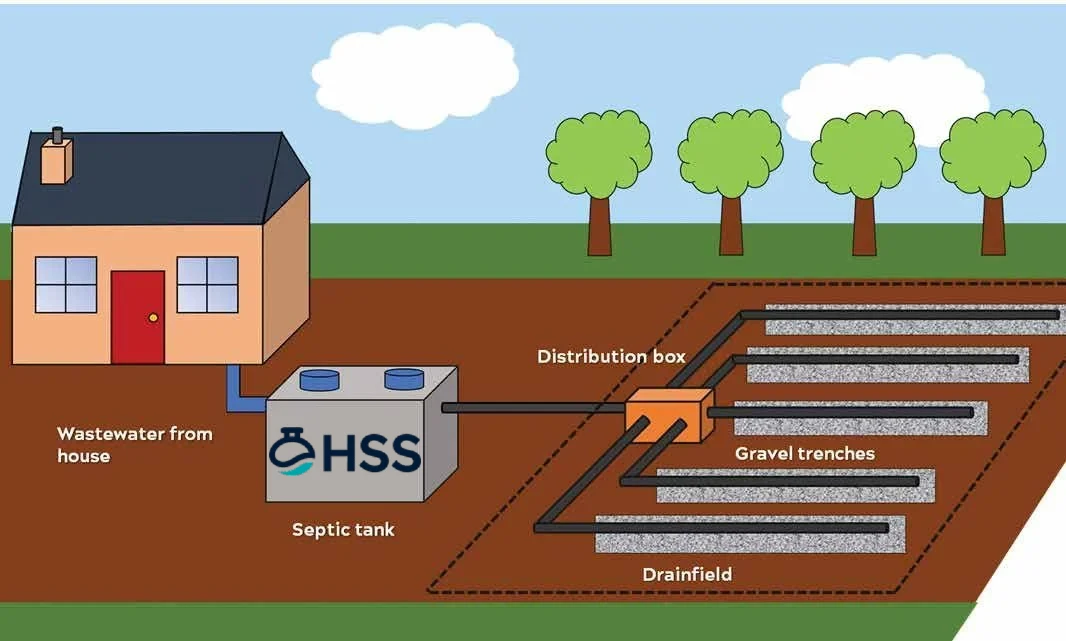

Conventional septic systems need deep, permeable soil and ample space. They rely on gravity to move liquid effluent (wastewater) from a tank into a network of underground trenches, where it slowly percolates through unsaturated soil for final treatment. This process fails on challenging sites due to five primary reasons:

According to the National Onsite Wastewater Recycling Association (NOWRA), the main causes for system denial are:

- Impermeable Soil (Clay): Dense clay particles prevent water movement, causing effluent to pool and surface.

- High Water Table: Seasonal groundwater rises into the proposed drain field area, eliminating the required unsaturated zone and risking contamination.

- Insufficient Depth (Bedrock/Ledgerock): Shallow bedrock prevents digging deep enough for a proper drain field.

- Limited Space: Small, narrow, or steep lots cannot accommodate the large, contiguous area needed for a conventional leach field while meeting setback rules.

- Environmental Restrictions: Proximity to lakes, streams, or wetlands requires advanced nitrogen/phosphate reduction, which basic systems cannot provide.

Bottom Line: If your site has one or more of these conditions, you must pursue an engineered alternative system. A licensed designer will determine the best fit based on your official site and soil evaluation.

How Do I Know Which Alternative Septic System I Need?

The correct system is determined by a licensed designer using your site’s specific data. However, you can match common challenges to general solution types. Use this diagnostic guide:

Quick Diagnostic Table: Match Your Problem to a Solution

| Your Primary Challenge | Best System Candidates | How It Overcomes the Challenge | Key Consideration |

|---|---|---|---|

| Slow Soil (Clay), High Water Table | Mound System, Sand Filter | Builds an elevated, sandy drain field above the natural grade and water table. | Requires significant space for the mound itself. |

| Poor Soil & Very Small Lot | Aerobic Treatment Unit (ATU) with Drip or Spray Field | Treats wastewater to a high standard, allowing shallow, small-area dispersal. | Higher maintenance costs & electrical dependency. |

| Small, Sloping, or Irregular Lot | Chamber System with Drip Dispersal | Uses flexible, shallow drip lines that can contour to tight or sloped spaces. | Requires meticulous filtration to prevent clogging. |

| Sensitive Environmental Area | Advanced ATU (Nitrogen-Reducing) | Provides tertiary treatment to remove pathogens and nutrients before dispersal. | Highest upfront and operational cost. |

How Does a Mound Septic System Work? (A Top Solution for Clay)

A mound septic system is a constructed, above-ground drain field for sites with poor soil or high water tables. It is the most common prescribed solution for clay-heavy sites that fail a perc test. Here is a step-by-step breakdown of the process:

Featured Snippet Target (List):

The key steps in mound system installation are:

- Site Preparation: The native soil is roughened to ensure a good bond with the imported sand.

- Sand Mound Construction: A specific grade of sand is hauled in and built into a precise, elevated mound.

- Distribution Network Installation: A network of pressurized perforated pipes is laid within the sand layer.

- Pump Chamber Integration: A pump tank receives effluent from the septic tank and pumps it up into the mound’s distribution pipes.

- Final Grading & Seeding: The mound is covered with topsoil and seeded with grass to prevent erosion.

According to the University of Minnesota Extension, a properly designed mound system provides effective treatment as the effluent filters through the sand before it ever reaches the restrictive native clay soil. It typically costs $15,000 to $35,000+ installed and requires annual inspections and pump tank maintenance.

Aerobic Treatment Unit (ATU): The High-Tech Solution for Small Lots

An Aerobic Treatment Unit (ATU) is an advanced mechanical septic system that uses oxygen to break down waste more efficiently. For small lots with poor soil, it’s often the only viable option.

Q: How is an ATU different from a regular septic tank?

A: A regular tank works anaerobically (without oxygen), providing basic settlement and partial breakdown. An ATU injects oxygen via an electric aerator, fostering aggressive bacteria that reduce waste to a much clearer, cleaner effluent—similar to municipal treatment plants. This high-quality output is what allows safe dispersal via a small spray or drip field on a compact lot.

Q: What is the maintenance cost for an aerobic system?

A: ATUs require professional maintenance contracts, typically costing $400 – $800+ annually for 2-4 service visits. Technicians check the aerator, pumps, chlorine tabs, and alarms. This non-negotiable cost ensures the system’s mechanical components function correctly and protect your investment.

Cost Analysis: DIY vs. Professional Installation

Engineered septic systems are NOT a DIY project. The design requires a licensed professional engineer’s stamp, and installation must be permitted and inspected by your local health department. Attempting DIY installation is illegal and will result in failed inspections and potential environmental hazards.

Professional Service Cost Ranges (Nationally):

| System Type | Average Installed Cost Range | Key Cost Drivers |

|---|---|---|

| Mound System | $18,000 – $35,000+ | Volume of imported sand, pump complexity, site access. |

| Aerobic Treatment Unit (ATU) | $22,000 – $40,000+ | Brand/model of ATU, type of dispersal field, maintenance contract. |

| Drip Irrigation System | $20,000 – $32,000+ | Filtration system quality, linear feet of drip tubing, terrain. |

| Sand Filter System | $16,000 – $28,000+ | Size of the filter bed, recirculating vs. single-pass design. |

Current Consensus: While the upfront cost is 2-3x that of a conventional system, an engineered system is the only capital investment that makes your challenging property livable and compliant, thereby preserving its full market value.

Frequently Asked Questions (FAQs)

Q: What is the cheapest alternative septic system?

A: For a site that only marginally fails a perc test, a larger-than-standard chamber system may be the lowest-cost alternative. For clearly poor soils, a single-pass sand filter is often less expensive than a full mound or ATU, but still averages $15,000-$25,000.

Q: How long do mound or aerobic systems last?

A: The tank and absorption area can last 25-40+ years with proper care. However, the mechanical components (pumps, aerators, alarms) have a shorter lifespan of 5-15 years and are a planned replacement cost.

Q: Can I plant trees or drive over my mound system?

A: No. The mound must remain undisturbed. Plant only grass or shallow-rooted flowers. Never drive, build, or pile materials on it, as this compacts the sand and destroys its treatment capacity.

Q: Are these systems bad for the environment?

A: Quite the opposite. According to the EPA, properly functioning engineered systems are designed to protect the environment in areas where conventional systems would pollute groundwater or surface water. They are a responsible solution for sensitive sites.

From Problem to Permitted Solution

While challenging site conditions present a significant hurdle, they are not an impasse. The field of onsite wastewater treatment has advanced precisely to address clay soils, small lots, and high water tables. The path forward requires partnering with a licensed septic designer and installer who specializes in engineered systems. By investing in the correct system—be it a mound, ATU, or drip dispersal—you secure the necessary permits, protect your local environment, and ultimately unlock the full potential of your property.

Your next step is clear: Stop worrying about the limitations of your land. Schedule a consultation with a local, licensed septic designer who can translate your site evaluation data into a custom, approved solution. Your dream property is still within reach.

Leave a Reply